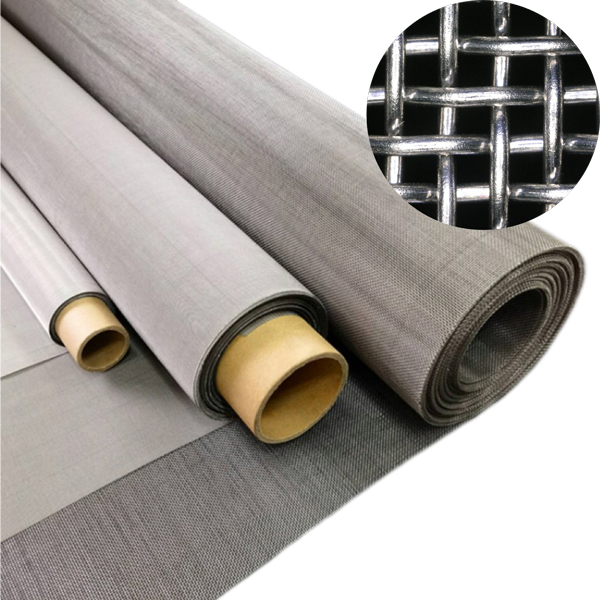

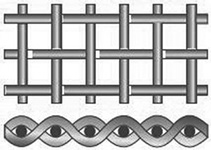

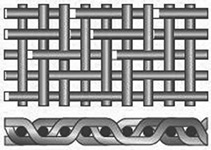

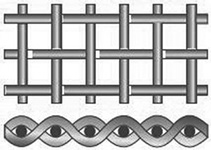

Plain Weave Square Mesh

Plain weave is the most fundamental and widely used weaving method for producing square mesh. Its structure is formed by alternately interlacing the weft wire over and under the warp wire, creating a clean, symmetrical pattern. Both warp and weft wires generally share the same diameter, which results in predictable and uniform mesh openings.

This weave type is preferred for:

- Coarse mesh specifications requiring stable aperture size

- Primary screening and sizing processes

- Protective layers in multilayer filtration assemblies

- Support mesh for filter elements and composite media

- General industrial barriers for separation, ventilation, and safety protection

With its simple geometry, plain weave offers excellent strength-to-weight balance and cost efficiency, making it suitable for applications where durability and consistent openings are essential.

Twill Weave Square Mesh

Twill weave achieves a denser, more robust structure by allowing each weft wire to pass alternately over and under two warp wires, with the pattern staggered from row to row. This construction supports the use of finer wire diameters while maintaining higher mesh counts and superior mechanical integrity.

Advantages include:

- Enhanced load-bearing capacity compared with plain weave

- Improved wire crimp stability for finer filtration grades

- Capability to produce fine to ultra-fine mesh with small, precise apertures

- Higher flexibility for demanding filtration and separation processes

Twill weave square mesh is widely used in high-precision environments such as fine chemical filtration, aerospace fluid systems, hydraulic assemblies, laboratory filtration, and industries where improved strength and filtration accuracy are required.

Applications Across Industries

- Petrochemical filtration systems

- Chemical processing and catalyst support

- Environmental protection equipment

- Mining and mineral screening

- Aerospace and hydraulic fluid filtration

- Electronic manufacturing processes

- Pulp and paper fiber separation

- Food and pharmaceutical processing

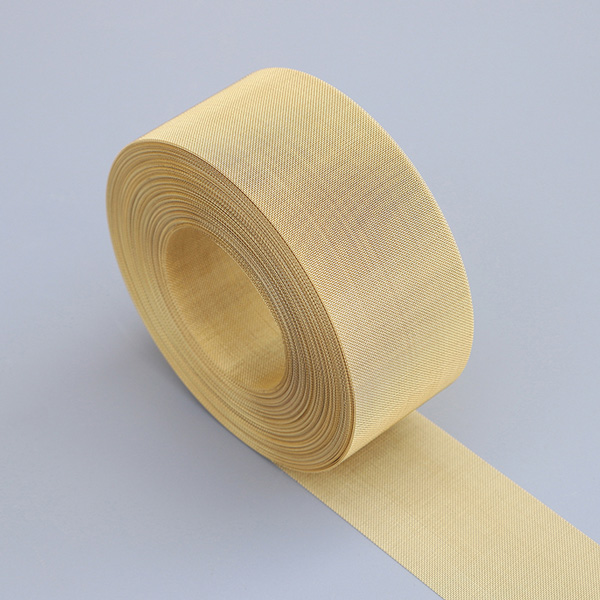

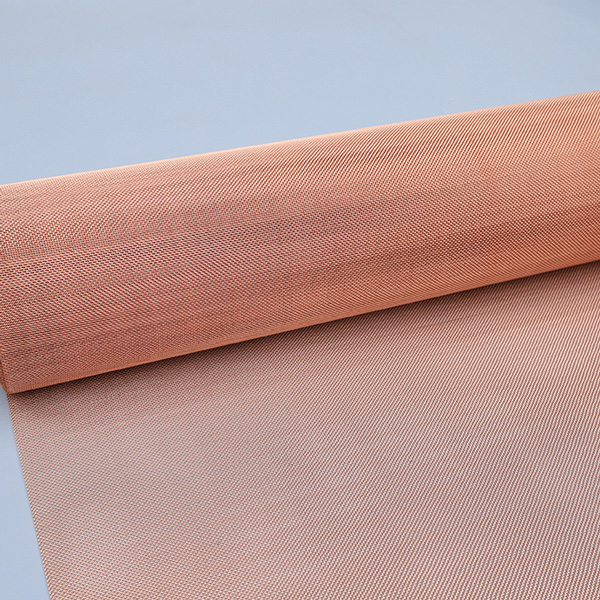

Material

Stainless Steel / Galvanized Iron / Copper / Brass (Cu=65%/80%) / Nickel / Monel / Titanium / Silver / Aluminum / Other Alloy / Epoxy Surface Finishing

Plain Weave Wire Mesh Specification

Mesh Count | Diameter | Opening | Open area |

mm | Inch | mm | Inch | % |

1×1 | 4.000 | 0.1570 | 21.400 | 0.8400 | 71 |

2×2 | 2.500 | 0.1180 | 10.200 | 0.3800 | 64.5 |

3×3 | 2.000 | 0.0790 | 6.400 | 0.2500 | 58 |

4×4 | 1.600 | 0.0630 | 4.750 | 0.1870 | 56 |

4×4 | 1.200 | 0.0470 | 5.150 | 0.2030 | 65.8 |

5×5 | 1.400 | 0.0550 | 3.680 | 0.1400 | 52.5 |

6×6 | 1.200 | 0.0470 | 3.030 | 0.1200 | 51.3 |

8×8 | 1.100 | 0.4300 | 2.080 | 0.0800 | 42.8 |

10×10 | 1.000 | 0.0390 | 1.540 | 0.0600 | 36.8 |

10×10 | 0.510 | 0.0200 | 2.030 | 0.0800 | 63.9 |

12×12 | 0.584 | 0.0230 | 1.520 | 0.0600 | 52.2 |

12×12 | 0.508 | 0.0200 | 1.600 | 0.0630 | 57.6 |

14×14 | 0.584 | 0.0230 | 1.220 | 0.0480 | 45.7 |

14×14 | 0.508 | 0.0200 | 1.300 | 0.0510 | 51.7 |

16×16 | 0.457 | 0.0180 | 1.130 | 0.0445 | 50.7 |

18×18 | 0.432 | 0.0170 | 0.980 | 0.0386 | 48.2 |

20×20 | 0.508 | 0.0200 | 0.760 | 0.0300 | 35.9 |

20×20 | 0.406 | 0.0160 | 0.860 | 0.0340 | 46.1 |

24×24 | 0.356 | 0.0140 | 0.700 | 0.0277 | 43.9 |

30×30 | 0.330 | 0.0130 | 0.520 | 0.0203 | 37.4 |

30×30 | 0.305 | 0.0120 | 0.540 | 0.0213 | 40.8 |

30×30 | 0.229 | 0.0090 | 0.620 | 0.0243 | 53.3 |

35×35 | 0.279 | 0.0110 | 0.450 | 0.0176 | 38.1 |

40×40 | 0.254 | 0.0100 | 0.380 | 0.0150 | 35.9 |

50×50 | 0.229 | 0.0090 | 0.280 | 0.0110 | 30.3 |

50×50 | 0.203 | 0.0080 | 0.310 | 0.0120 | 36.5 |

60×60 | 0.191 | 0.0075 | 0.230 | 0.0092 | 29.8 |

60×60 | 0.178 | 0.0070 | 0.250 | 0.0097 | 34.1 |

70×70 | 0.165 | 0.0065 | 0.200 | 0.0078 | 30 |

80×80 | 0.140 | 0.0055 | 0.180 | 0.0070 | 31.6 |

80×80 | 0.120 | 0.0047 | 0.197 | 0.0077 | 38.6 |

90×90 | 0.127 | 0.0050 | 0.160 | 0.0061 | 31.1 |

100×100 | 0.114 | 0.0045 | 0.140 | 0.0055 | 30.4 |

100×100 | 0.102 | 0.0040 | 0.150 | 0.0060 | 35.4 |

100×100 | 0.089 | 0.0035 | 0.170 | 0.0065 | 43.1 |

110×110 | 0.102 | 0.0040 | 0.130 | 0.0051 | 31.4 |

120×120 | 0.094 | 0.0037 | 0.117 | 0.0046 | 30.7 |

150×150 | 0.060 | 0.0026 | 0.104 | 0.0041 | 40.2 |

160×160 | 0.064 | 0.0025 | 0.097 | 0.0038 | 36.4 |

180×180 | 0.058 | 0.0023 | 0.084 | 0.0033 | 34.7 |

200×200 | 0.053 | 0.0021 | 0.074 | 0.0029 | 33.7 |

250×250 | 0.040 | 0.0016 | 0.061 | 0.0024 | 36.5 |

270×270 | 0.040 | 0.0016 | 0.054 | 0.0021 | 33 |

300×300 | 0.040 | 0.0016 | 0.045 | 0.0018 | 27.8 |

325×325 | 0.036 | 0.0014 | 0.043 | 0.0017 | 30.1 |

400×400 | 0.030 | 0.0011 | 0.033 | 0.0015 | 27.4 |

500×500 | 0.025 | 0.0010 | 0.025 | 0.0010 | 25 |

635×635 | 0.020 | 0.0008 | 0.020 | 0.0008 | 25 |