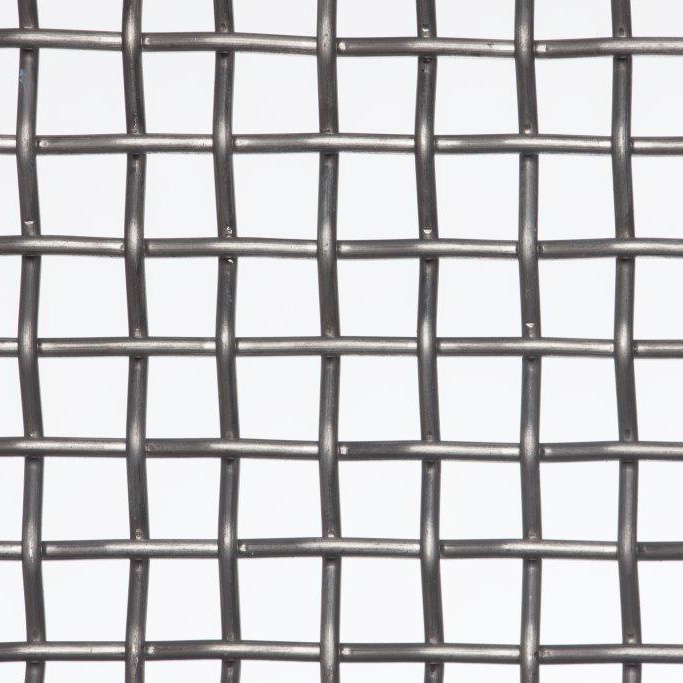

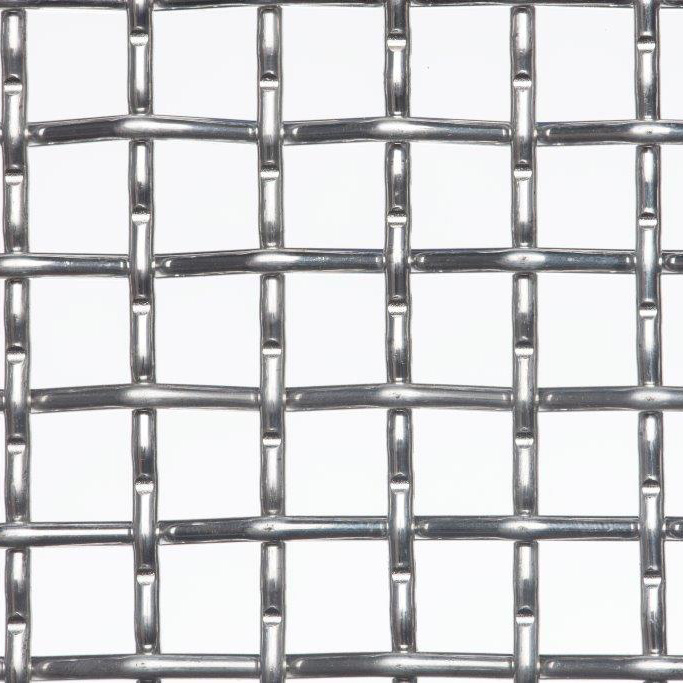

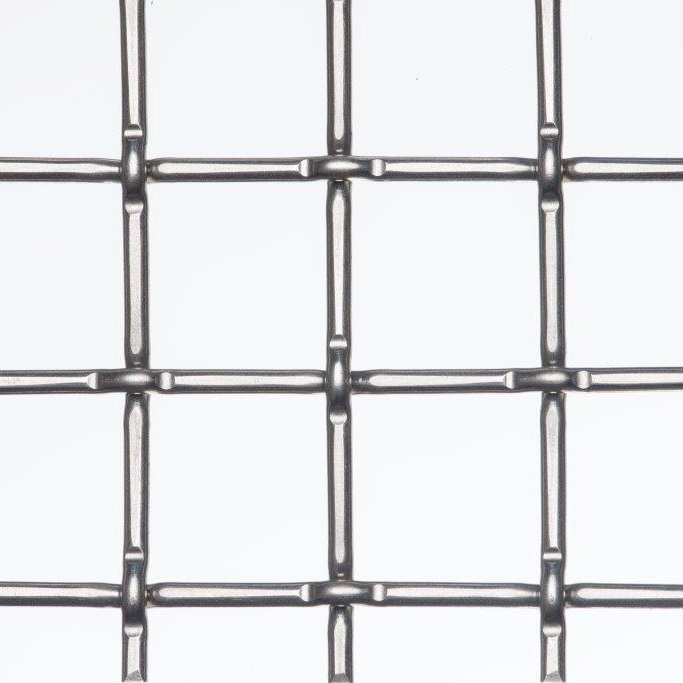

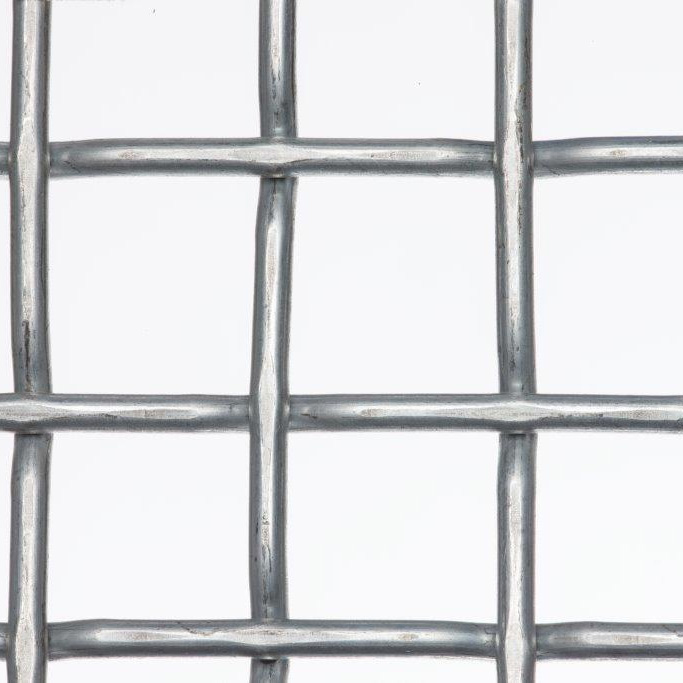

Crimped Wire Mesh

Crimped wire mesh is a precision-woven wire cloth produced by pre-crimping the wires before weaving. This pre-crimping process forms uniform undulations on the warp and weft wires, locking them securely at each intersection. By preventing wire movement during weaving, pre-crimping ensures precise openings, consistent tension, and improved rigidity—attributes that are essential for heavy-duty or load-bearing mesh applications. The result is a stable, rigid mesh structure with excellent dimensional accuracy and an attractive textured appearance.

Crimped mesh is valued for its combination of mechanical strength, load-bearing capacity, and aesthetic appeal, making it suitable for both architectural and industrial applications.

Key Features

Pre-crimped construction ensures tight locking and rigid weave

Stable aperture size with consistent tension across the mesh

Enhanced structural integrity for heavy-duty or load-bearing use

Distinct decorative appearance suitable for architectural projects

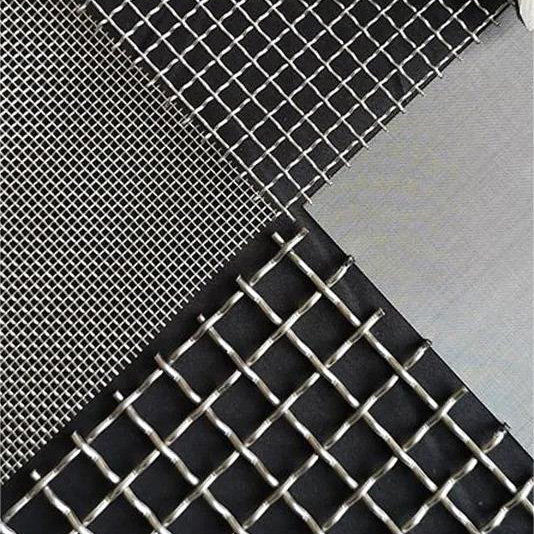

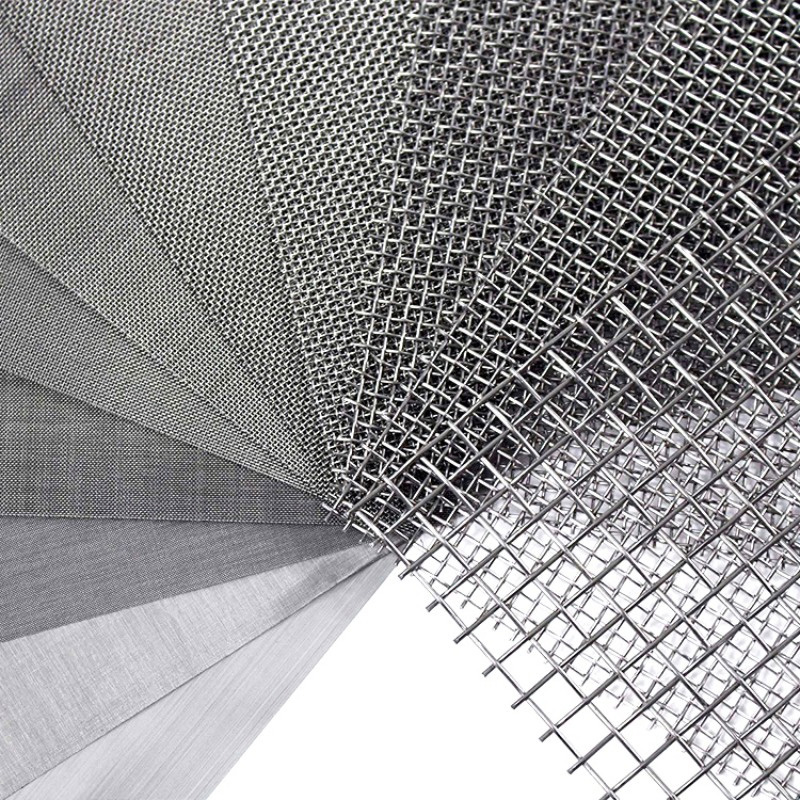

Available in multiple crimp styles for functional and aesthetic flexibility

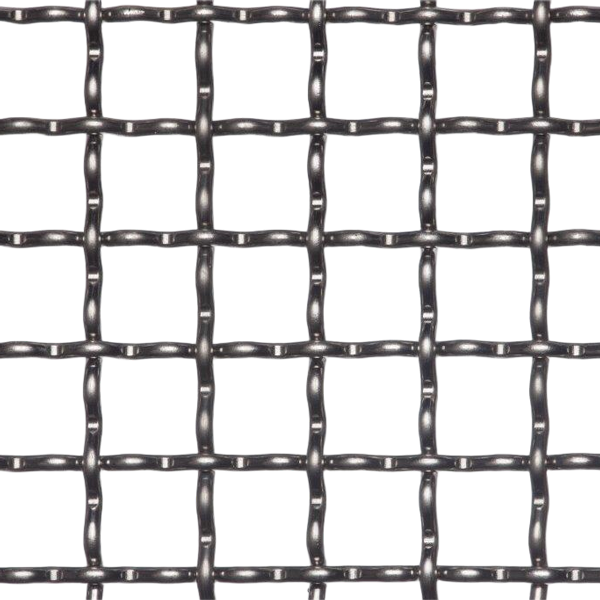

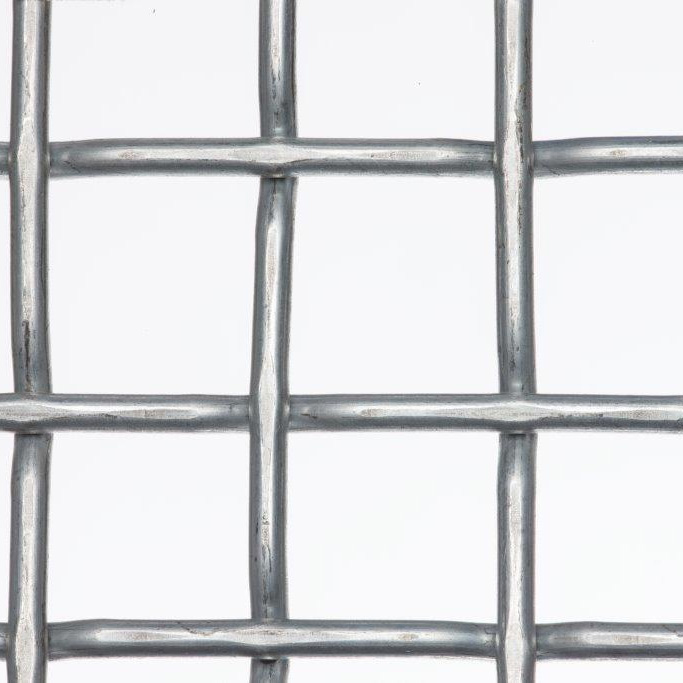

Intermediate Crimped Wire Mesh

Uses alternating crimps to stabilize larger openings. Suitable for screening, filtration, and applications requiring strength with moderate transparency.

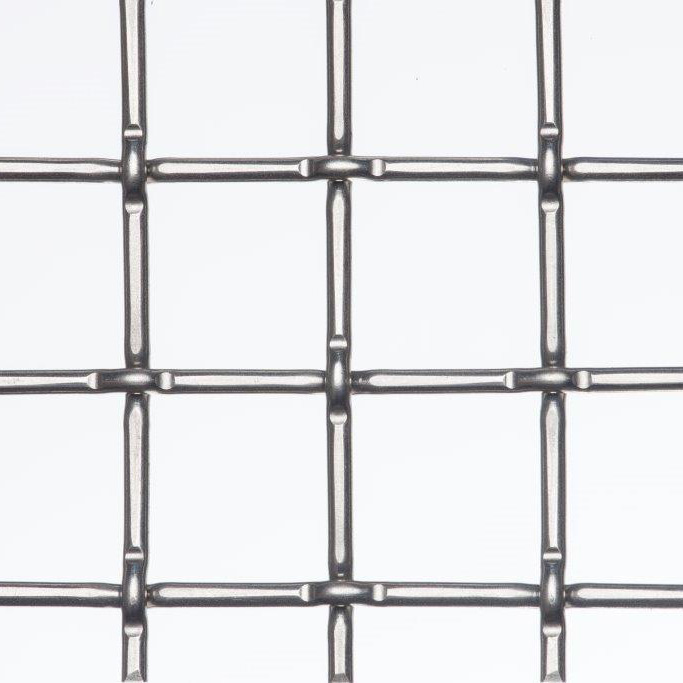

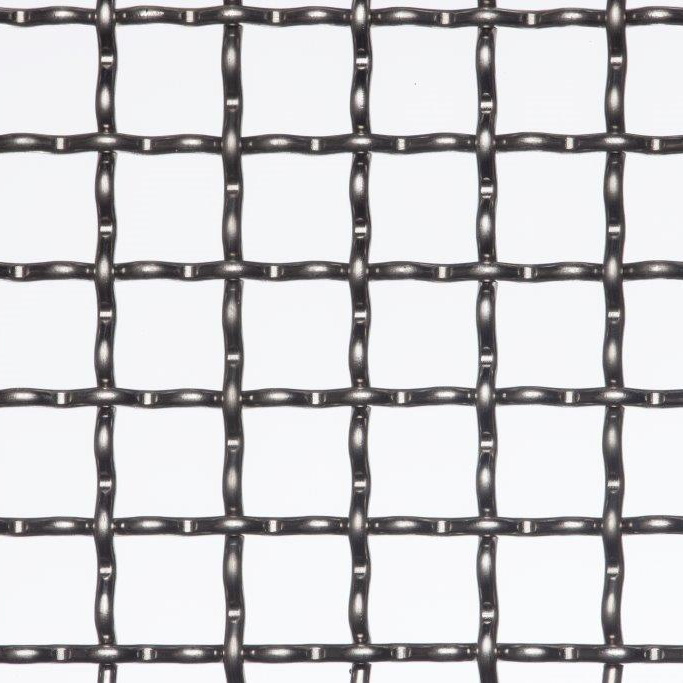

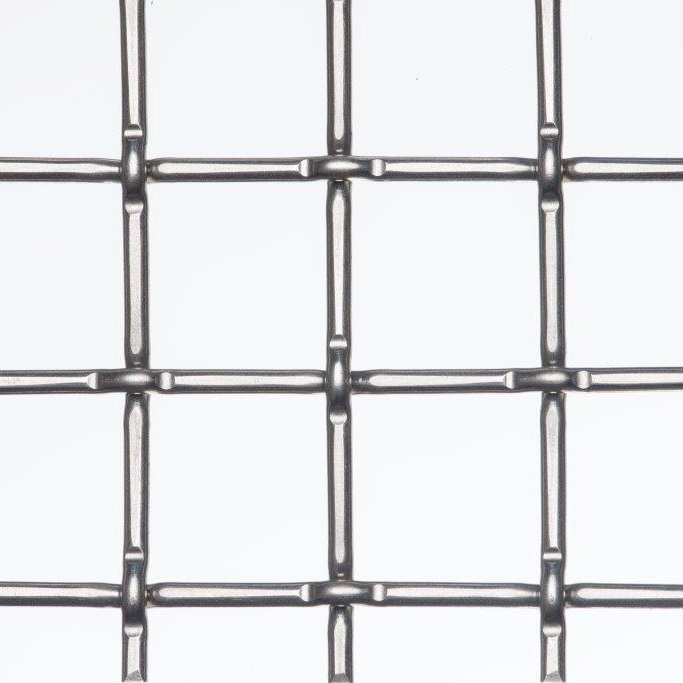

Lock Crimped Wire Mesh

Features an interlocking crimp at every intersection. Provides a tight, smooth, stable weave ideal for architectural infill panels, grills, and high-spec finishes.

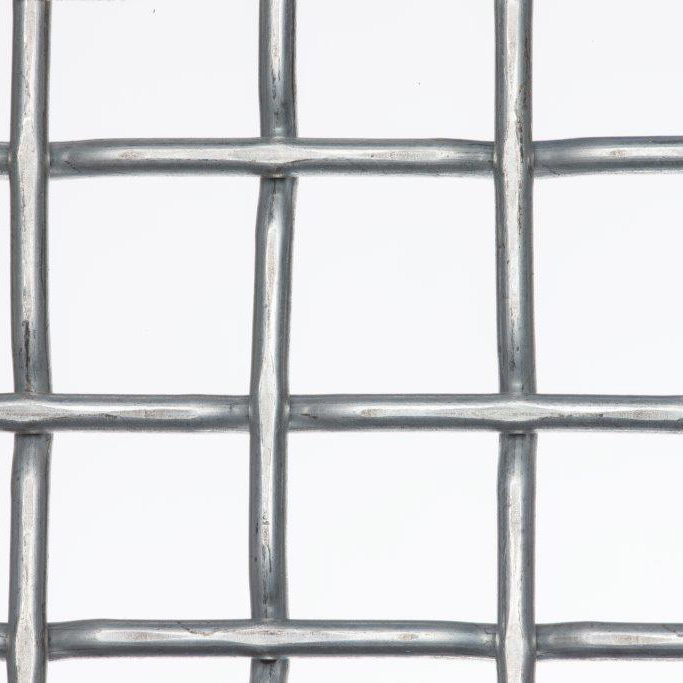

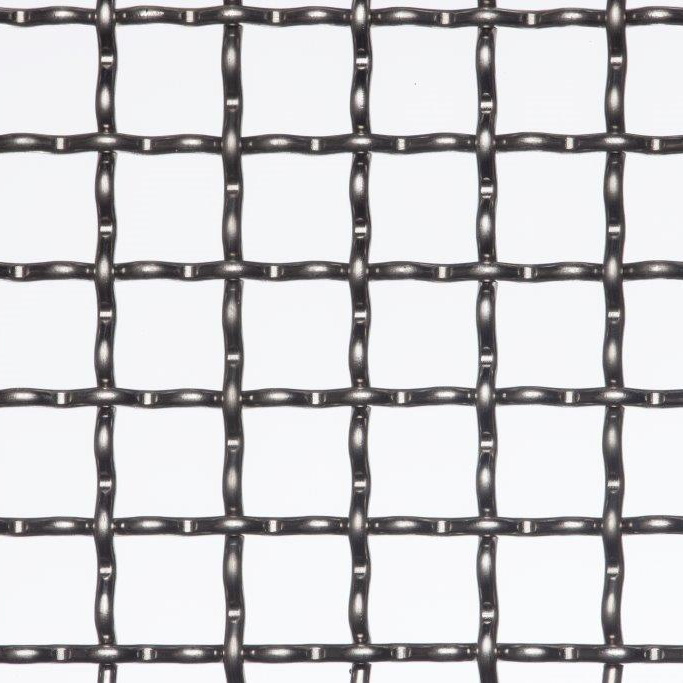

Flat Top Crimped Wire Mesh

One side is completely flat, improving material flow and reducing abrasion. Often used for screening, ventilation panels, and applications where a smooth surface is desirable.

Material

Stainless Steel

Plain / Carbon Steel

Aluminum

Brass (Cu=65%/80%)

Copper

Specialty Alloys