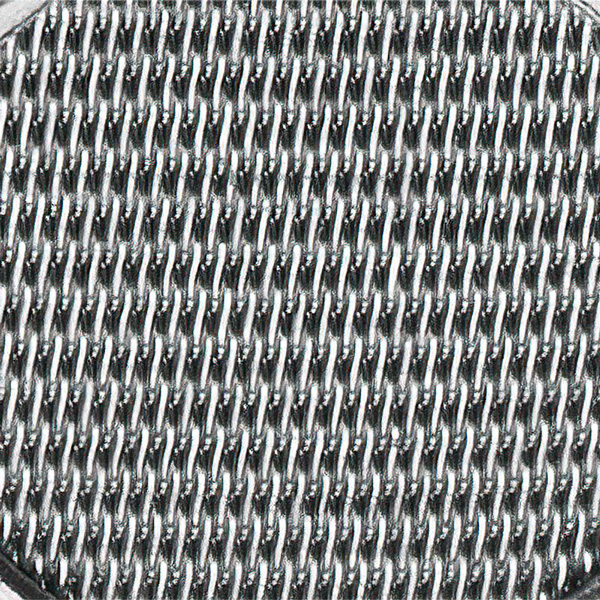

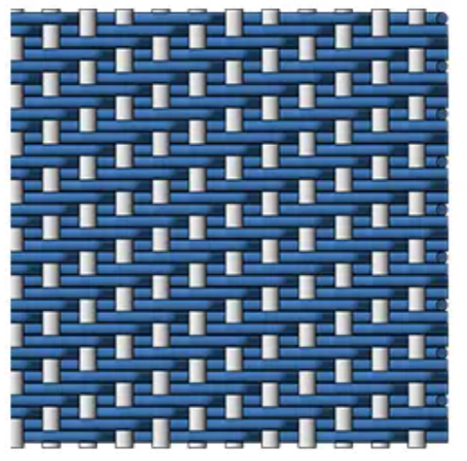

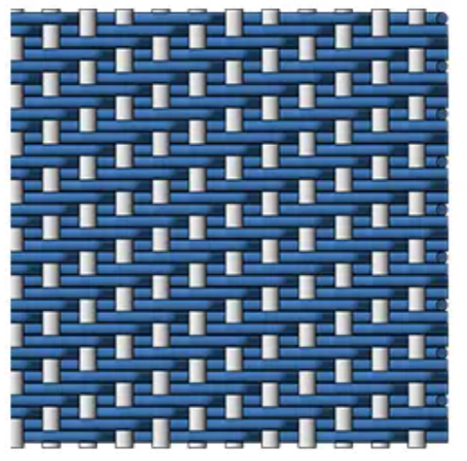

Plain Dutch Weave

Similar to plain weave, but the diameter of the warp wire is larger than the weft wire. During weaving, the finer weft wires are driven closer together to form a tight filter medium with higher filtration rating and greater strength than plain weave. It also creates tapered or wedge-shaped openings. Typically, coarse mesh functions as the reinforcing layer of metal sintered mesh, while fine mesh serves as the filtration layer.

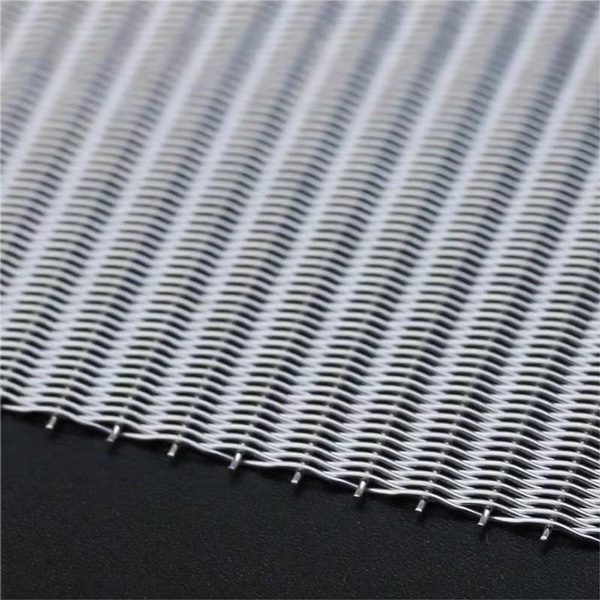

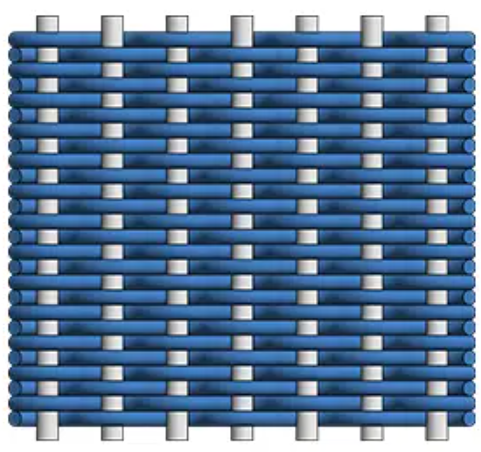

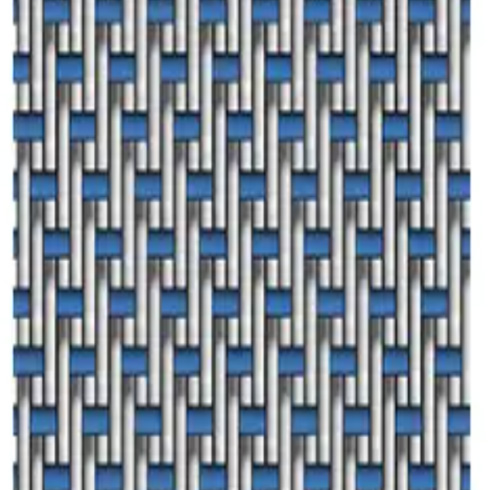

Twill Dutch Weave

This weave combines Dutch and twill weaving techniques. Each warp wire alternately passes over and under two fine weft wires. The weft wires are packed densely, forming a compact mesh structure with tapered or wedge-shaped openings and smaller aperture sizes. Coarse mesh is used as the reinforcement layer of sintered mesh, and fine mesh forms the filtration layer.

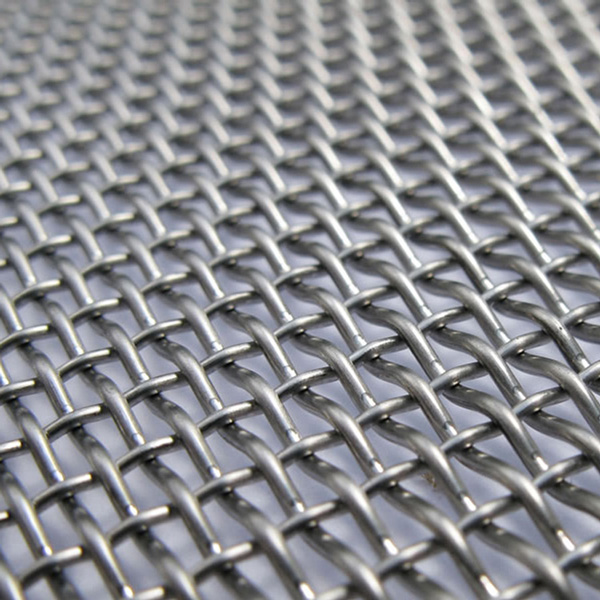

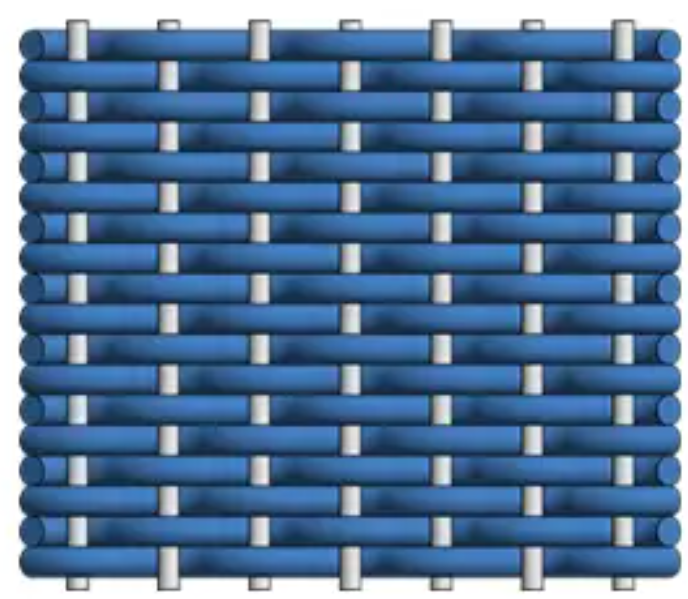

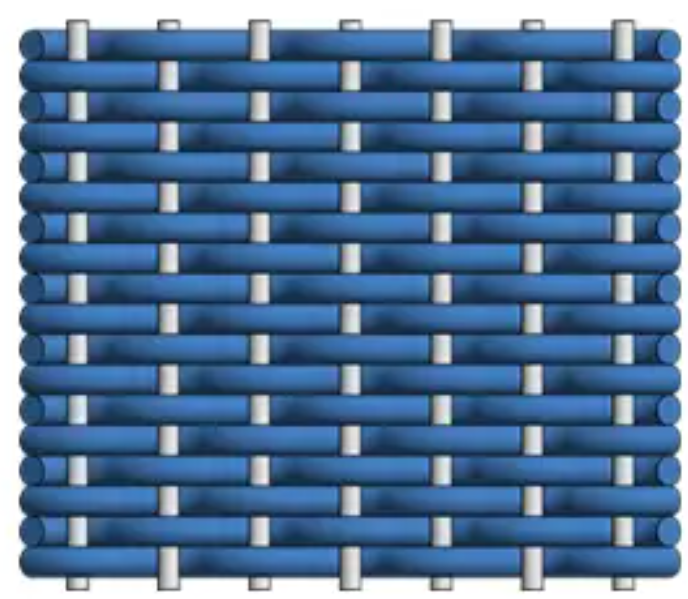

Reverse Dutch Weave

Reverse Dutch Weave arranges the wire sequence opposite of Plain Dutch Weave, using smaller warp wires and larger weft wires. The smaller warp wires form a tight filtration structure, while the larger weft wires provide higher mechanical strength, increasing the mesh’s durability and service life.

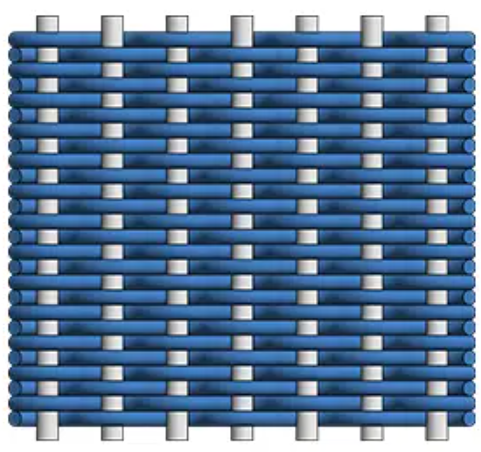

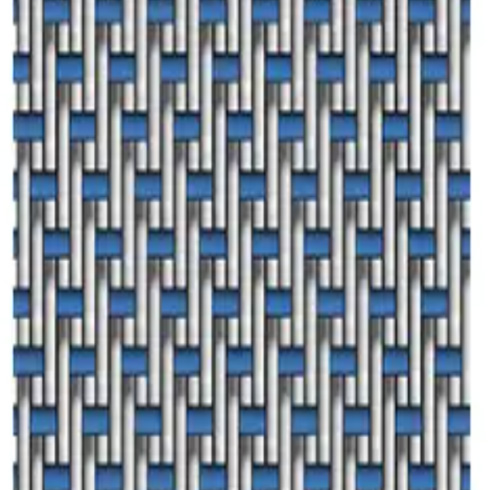

Reverse Dutch Twill Weave

Reverse Dutch Twill Weave combines the structural characteristics of Reverse Dutch Weave with the enhanced strength of the twill pattern. In this configuration, smaller warp wires and larger weft wires are woven in a twill sequence, where each warp wire passes alternately over and under two adjacent weft wires. The fine warp wires create an exceptionally tight filtration structure, while the thicker weft wires deliver superior mechanical strength, improved durability, and greater deformation resistance. This weave is ideal for high‑pressure, high‑viscosity, or continuous mechanical‑load filtration conditions.

Material

Stainless Steel / Galvanized Iron / Copper / Brass (Cu=65%/80%) / Nickel / Monel / Titanium / Silver / Aluminum / Other Alloy / Epoxy Surface Finishing

Plain dutch weave

|

|

|

|

|

|

Mesh count | Diameter | Abs.filtering | Nominal filtering | Max width |

mm | Inch | μm | μm | mm |

8×85 | 0.36×0.32 | 0.0140×0.0126 | 300-320 | 310 | 2000 |

12×64 | 0.61×0.42 | 0.0240×0.0165 | 260-280 | 250 | 2000 |

12×90 | 0.45×0.30 | 0.0178×0.0120 | 270-300 | 211 | 2000 |

14×88 | 0.51×0.33 | 0.0200×0.0130 | 255-275 | 250 | 2000 |

14×100 | 0.41×0.28 | 0.0160×0.0110 | 235-260 | 182 | 2000 |

16×80 | 0.43×0.34 | 0.0170×0.0135 | 210-230 | 260 | 2000 |

16×100 | 0.40×0.28 | 0.0157×0.0110 | 200-220 | 160 | 2000 |

16×120 | 0.36×0.24 | 0.0140×0.0094 | 180-198 | 150 | 2000 |

20×150 | 0.25×0.18 | 0.0098×0.0070 | 155-185 | 120 | 2000 |

24×110 | 0.38×0.25 | 0.0150×0.0100 | 115-128 | 110 | 2000 |

30×150 | 0.23×0.18 | 0.0090×0.0070 | 90-105 | 90 | 2000 |

30×280 | 0.28×0.09 | 0.0110×0.0037 | 100-110 | 100 | 2000 |

40×200 | 0.18×0.14 | 0.0070×0.0055 | 70-80 | 70 | 2000 |

40×340 | 0.25×0.08 | 0.0098×0.0030 | 78-84 | 75 | 2000 |

50×250 | 0.14×0.11 | 0.0055×0.0045 | 52-57 | 55 | 2000 |

50×280 | 0.14×0.10 | 0.0055×0.0040 | 50-55 | 50 | 2000 |

50×460 | 0.20×0.06 | 0.0078×0.0023 | 60-65 | 60 | 1300 |

60×500 | 0.17×0.05 | 0.0065×0.0020 | 48-54 | 50 | 1300 |

70×350 | 0.13×0.08 | 0.0050×0.0030 | 41-47 | 35 | 1300 |

70×620 | 0.15×0.05 | 0.0060×0.0018 | 45-48 | 45 | 1300 |

80×300 | 0.13×0.09 | 0.0050×0.0035 | 45-50 | 45 | 1300 |

80×400 | 0.13×0.07 | 0.0050×0.0028 | 40-45 | 40 | 1300 |

80×700 | 0.10×0.03 | 0.0040×0.0013 | 35-44 | 35 | 1300 |

|

|

|

|

|

|

Twill dutch weave |

|

|

|

|

|

|

|

|

|

|

Mesh count | Diameter | Abs.filtering | Nominal filtering | Max width |

mm | Inch | μm | μm | mm |

20×250 | 0.254×0.200 | 0.0100×0.0080 | 100-118 | 100 | 2000 |

30×360 | 0.254×0.152 | 0.0100×0.0060 | 95-105 | 90 | 2000 |

40×560 | 0.178×0.102 | 0.0070×0.0040 | 75-83 | 65 | 2000 |

50×250 | 0.254×0.200 | 0.0100×0.0080 | 55-60 | 50 | 2000 |

80×700 | 0.102×0.076 | 0.0040×0.0030 | 35-38 | 35 | 1600 |

200×600 | 0.061×0.046 | 0.0024×0.0018 | 28-32 | 30 | 1600 |

165×800 | 0.071×0.051 | 0.0028×0.0020 | 25-39 | 25 | 1300 |

165×1400 | 0.071×0.041 | 0.0028×0.0016 | 16-18 | 15 | 1300 |

200×1400 | 0.071×0.041 | 0.0028×0.0016 | 12-14 | 10 | 1300 |

250×1400 | 0.056×0.041 | 0.0022×0.0016 | 11-13 | 9 | 1300 |

325×2300 | 0.038×0.025 | 0.0015×0.0010 | 8-9 | 5 | 1300 |

400×2800 | 0.028×0.020 | 0.0011×0.0008 | 4-5 | 2 | 1300 |

500×3600 | 0.025×0.014 | 0.0010×0.0006 | 2-3 | 1 | 1300 |

|

|

|

|

|

|

Reverse plain dutch weave |

|

|

|

|

|

|

|

|

|

|

Mesh count | Diameter | Abs.filtering | Nominal filtering | Max width |

mm | Inch | μm | μm | mm |

130×30 | 0.200×0.450 | 0.0079×0.0177 | 100-110 | 100 | 1800 |

128×36 | 0.200×0.400 | 0.0079×0.0157 | 80-90 | 80 | 1800 |

175×50 | 0.150×0.300 | 0.0059×0.0118 | 60-70 | 60 | 1300 |

290×60 | 0.090×0.230 | 0.0035×0.0090 | 43-51 | 51 | 1300 |

290×74 | 0.090×0.200 | 0.0035×0.0079 | 38-45 | 40 | 1300 |

625×105 | 0.042×0.140 | 0.0016×0.0055 | 23-28 | 25 | 1300 |

630×134 | 0.040×0.130 | 0.0015×0.0051 | 18-23 | 17 | 1300 |

720×150 | 0.035×0.110 | 0.0013×0.0043 | 16-20 | 14 | 1300 |

|

|

|

|

|

|

Reverse twill dutch weave |

|

|

|

|

|

|

|

|

|

|

Mesh count | Diameter | Abs.filtering | Nominal filtering | Max width |

mm | Inch | μm | μm | mm |

48×10 | 0.500×0.500 | 0.0200×0.0200 | 350-450 | 400 | 1300 |

72×15 | 0.500×0.500 | 0.0200×0.0200 | 250-350 | 300 | 1300 |

132×16 | 0.352×0.457 | 0.0140×0.0180 | 210-260 | 250 | 1300 |

132×18 | 0.355×0.455 | 0.0140×0.0179 | 180-220 | 200 | 1300 |

152×24 | 0.315×0.350 | 0.0120×0.0140 | 115-130 | 165 | 1300 |

260×40 | 0.150×0.220 | 0.0059×0.0086 | 80-95 | 125 | 1300 |

325×39 | 0.150×0.300 | 0.0059×0.0120 | 45-75 | 55 | 1300 |

345×45 | 0.140×0.230 | 0.0055×0.0090 | 40-65 | 50 | 1300 |

400×120 | 0.065×0.100 | 0.0026×0.0040 | 60-70 | 60 | 1300 |